With colder weather approaching, it is a good time to consider performing an Infrared (IR) Scan on your facility’s building envelope, specifically the wall assemblies this time of year. IR Scans help you to understand the conditions of your building envelope that are invisible to the naked eye, giving you a more comprehensive understanding of your building’s performance. The non-invasive, non-destructive inspection process identifies:

- thermal variances within the wall insulation systems

- moisture penetration into the wall assembly

- moisture laden insulation

- air infiltration and exfiltration through the fenestrations (doors, windows and skylights)

- radiant floor heat

- and other applications that relate to the building envelope.

Not only do IR scans reveal performance issues that may have gone unnoticed, but they can significantly reduce the number and size of areas that may need more expensive and invasive investigation.

New Construction IR Scans

IR scans are becoming increasingly popular with new construction projects. The primary reason is to identify any breaks in the thermal barrier. These breaks are typically a result of either errors made during the design process and inadequate detailing, or workmanship errors made during construction. Thermal breaks happen where different wall systems interface and require seams – wall and window, wall and roof, wall and door, etc. IR Scans are frequently used in conjunction with building pressurization test, which use either a blower door or the building’s HVAC equipment to more easily identify infiltration/exfiltration sites within the wall assemblies.

On average, the building envelope constitutes for about 20% of the total building construction cost, but results in 80% of construction defect claims. Of that 80 percent, façade defect claims make up over 40%. This realization is why building owners are turning to post-construction IR scans to confirm the quality of workmanship and synergy of building materials.

Restoration and Retro-Commissioning IR Scans

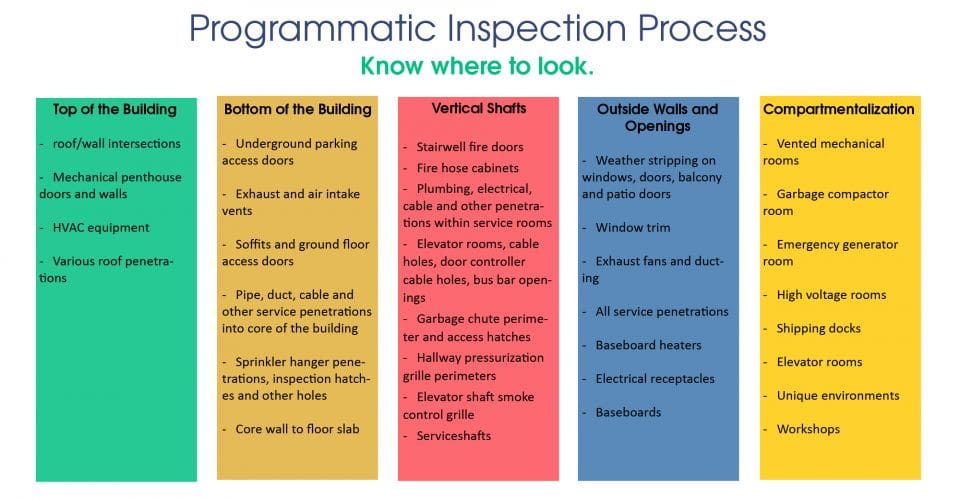

IR Scans are also used in restoration projects and in preventative maintenance applications, especially on buildings suffering from leaks and moisture build-up. The scans help building owners fully understand how the building operates under extreme conditions so that we can reduce heating and cooling costs, and increase overall energy efficiency. By identifying and resolving problem areas within the air barriers, building owners can reduce air leakage by up to 85%, saving up to 40% in gas and up to 25% in electricity costs in heating dominated climates. They are frequently incorporated into condition assessments to help establish a baseline before repair, restoration or replacement design begins. The key to these assessments is knowing where to look (see image below) to make sure you have a sealed envelope. These areas include the top and bottom of the building, vertical shafts, outside walls and openings and compartmentalized systems within the facility.

How IR Scans Works

IR Scans of the facade and wall systems should be planned for late night or early morning to avoid the false readings caused by direct sunlight. Direct sunlight will warm the surfaces that will be scanned. In some cases, materials with a high thermal mass, such as brick or stone, can retain heat well into the middle of the night. Each building presents different situations that may or may not be acceptable for a quality IR Scan. There should also be a minimum of 20° difference between the inside and outside temperatures (the larger the difference the better). A trained and qualified thermographer or building enclosure specialist will be able to identify sources of false readings and can guide you in establishing the appropriate time to execute the infrared scan. During the scan, a complete walk-through of the building enclosure is conducted. The building enclosure specialist will then be able to interpret the infrared images to identify any defects that may be present in the systems.